WCS insights June 2024

The 40MW Windcatcher unit achieves Approval in Principle (AiP) from DNV, marking an important milestone toward the Windcatcher demonstrator project.

The 40MW Windcatcher design receives Approval in Principle (AiP) from DNV

Ørjan Fredriksen, VP Global Design

An important milestone on the route to commercial demonstration of the Windcatcher technology is now reached with an AiP from DNV.

Over the last six months, our team has been focused on further maturing the Windcatcher technology through maturing the 40MW Windcatcher design. A key milestone has been to achieve an Approval in Principle from DNV, and we are happy to announce that this milestone has now been reached.

The objective of an AiP is to perform a third-party technical evaluation of a design to assess whether there are any conceptual showstoppers or rule compliance aspects that need improvement. As such, a successful AiP indicates the likelihood of the design meeting applicable rule criteria for future DNV classification.

Strong partnerships

The technical development work leading up to the AiP has been a joint effort with our engineering partners Aibel and Arup, who have supported with in-depth knowledge and experience in advanced simulations and design of offshore structures. This work has covered a range of engineering disciplines including structural and marine design, stability and hydrodynamics, mooring system arrangement, layout and technical safety, and transport and installation.

As a supplement to the engineering work, a physical model test campaign was performed at Stadt Towing Tank in Måløy, Norway. The purpose of the campaign was to better understand how the Windcatcher performs in various wave conditions, and further use this insight to validate and calibrate our analysis models and assumptions.

Commercial demonstrator

Wind Catching Systems, through its subsidiary Wind Catching Demo AS has started the process towards a licence for a demonstrator project off the coast of Øygarden, Norway. The 40MW design that has now achieved the AiP will be the first out of four expected units in the project.

The AiP process has provided clear direction for the further development and optimisation of the Windcatcher and highlighted important focus areas, and marks an important milestone for our commercial demonstrator project.

WCS insights April 2024

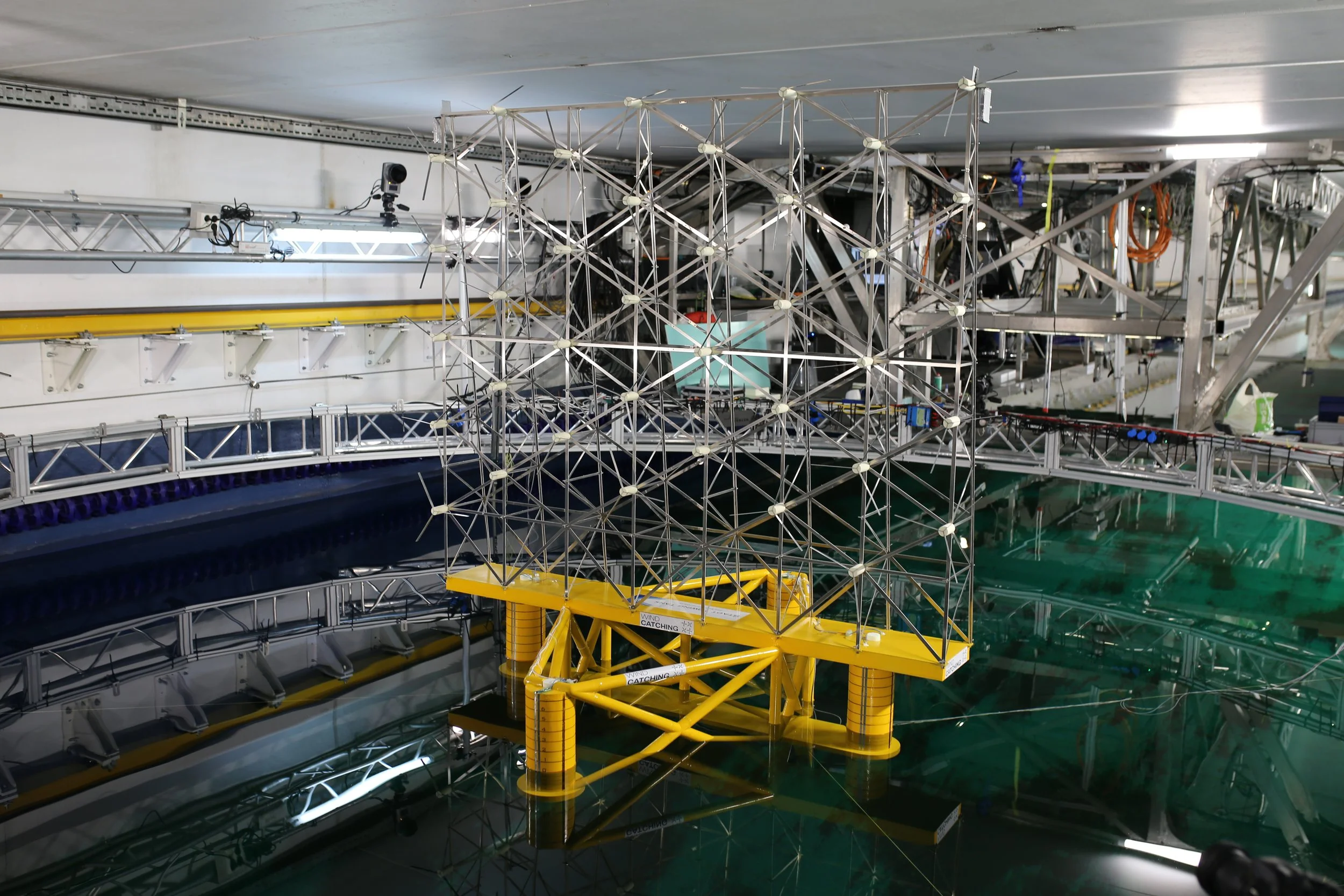

A physical model of the Windcatcher was recently tested at the Stadt Towing Tank As in Måløy, Norway. The test campaign showed high correlation with simulations and demonstrated the excellent hydrodynamic performance of the Windcatcher.

The Windcatcher model test

Ørjan Fredriksen, VP Global Design

A physical model of the Windcatcher was recently tested at Stadt Towing Tank in Måløy, Norway. Measuring about 2 meters in all directions at 1:87.5 scale, the model was used to better understand how the concept behaves when exposed to hydrodynamic loads. The physical test campaign has provided valuable input to our technology development, confirming the favourable performance of the Windcatcher in a range of environmental conditions.

Floater behaviour in extreme waves of 11.7 m significant height, corresponding to a 100-year design condition

During the test campaign, we studied a range of wave conditions, both regular wave trains and irregular wave spectra. Several oblique sea states were run to verify performance of the Windcatcher when exposed to weather conditions with misalignment between wind and waves. Although usually less severe, such conditions are of importance with respect to floater stability, mooring system design, airgap, and structural fatigue. With a design life of 50 years, fatigue is a limit state of critical importance in the structural engineering of the floater and turbine supporting structure. Floater motions and accelerations, mooring line forces, and relative surface elevation were recorded at multiple positions to establish a detailed dataset as basis for further engineering works.

Floater behaviour during 1-year sea condition with waves coming at a 30-degree angle

In addition to a range of seakeeping tests, we carried out a set of free decay tests to confirm natural frequencies of the Windcatcher, as well as to verify the hydrodynamic damping coefficients of the floater. Decay tests were performed for heave, roll and pitch motions, both with and without mooring lines connected. Furthermore, we performed a series of calm water towing tests at different speeds and angles. Our main motivation for these tests was to establish accurate drag coefficients of the floater to be applied in coupled simulations that include combined action from wind, waves and currents. However, the towing tests also provided useful insights to be considered in further development of our transport and installation philosophy.

As always, it is reassuring to observe good agreement between simulations and physical tests, and we are very pleased to see that the excellent hydrodynamic performance of the Windcatcher is confirmed through this test campaign.

Towing test at 1.5 m/s speed

WCS insights December 2023

Standardization and scale are the two central pillars of cost reduction for floating wind. Bringing the two together is key to our vision of unleashing the power of offshore wind.

Floating wind – More on less

Ole Heggheim, CEO, Wind Catching Systems

So much more of the future economy may find its foundations offshore, than the economy of the past decades. As we build new industries on the high seas, the need increases to find acreage efficient solutions. At Wind Catching Systems we have co-existence as a core value. The Windcatcher technology gives credit to that promise.

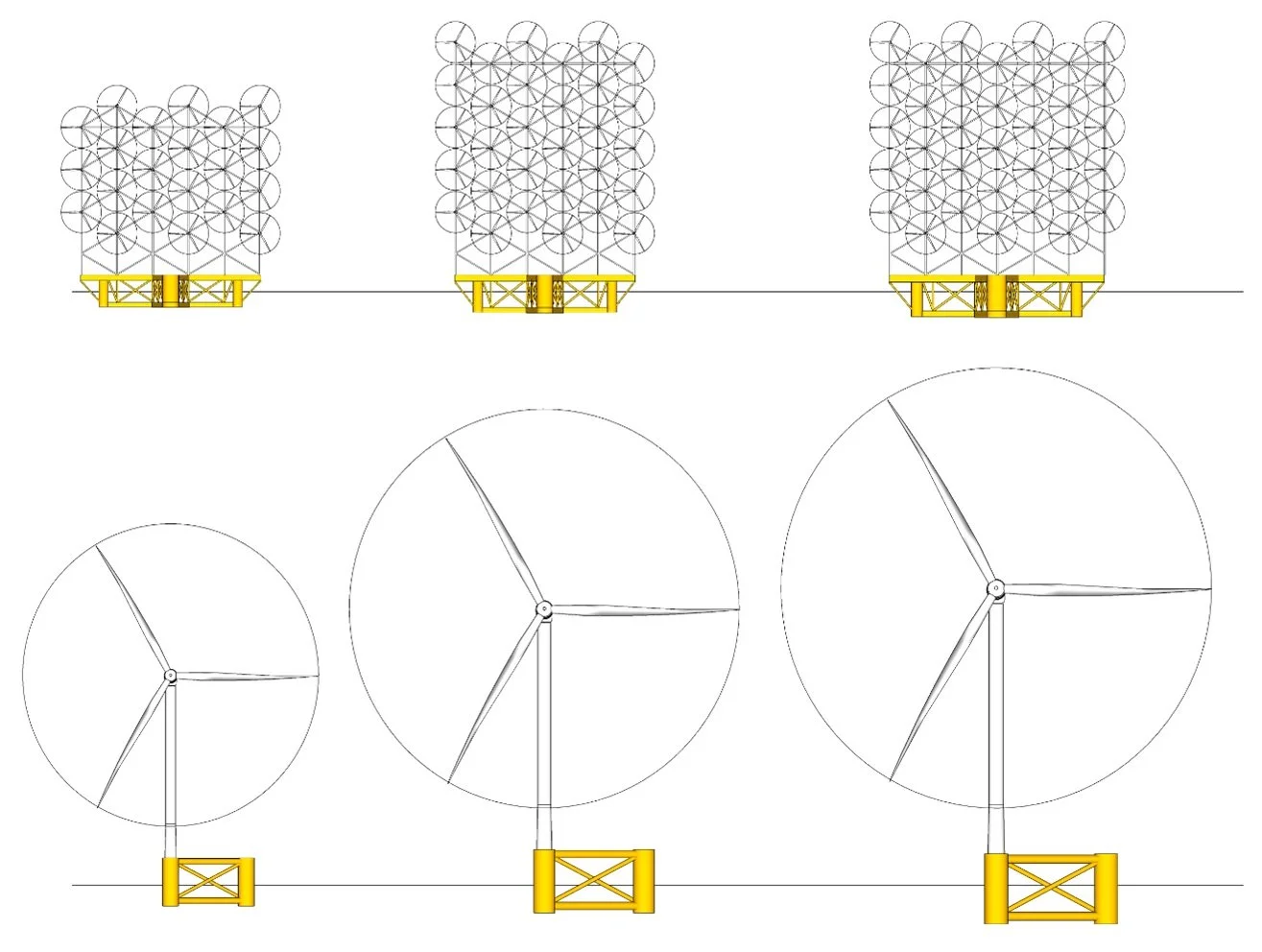

The Windcatcher system is designed with one primary thought in mind: Maximizing the energy yield per floating unit of offshore wind. With the ability to scale the system with the number of identical turbines, rather than with the size of each turbine, and the use of standardization and mass production that follows, the Windcather may concentrate a lot of power production. In fact, the largest models of the system may use only 1/5 of the acreage compared to using the largest available singe turbines available today in single-turbine configuration.

Using fewer units to produce the renewable energy also means that the eco-system impact is reduced. While a Windcatcher may be an impressively large structure, it is moored to the seabed in the same fashion as conventional systems. The Windcatcher technology thus has no larger impact on the seabed than a single-turbine system, but its impact on the energy transition is that much more profound. More for less, in short.

Reducing the ecosystem impact from new energies and achieving lasting co-habitation with the other industries in the ocean is not a nice-to-have in offshore wind, it is essential. That is why co-existence is a core value of Wind Catching Systems, and the Windcatcher delivers on that promise.

WCS insights December 2023

Standardization and scale are the two central pillars of cost reduction for floating wind. Bringing the two together is key to our vision of unleashing the power of offshore wind.

Floating wind – Standardizing the floating turbine

Ole Heggheim, CEO, Wind Catching Systems

Standardization and scale are the two central pillars of cost reduction for floating wind, and for offshore wind in general. So far, the two have been at odds. Breaking that trend brings the benefit of being able to standardize the turbine, and accessing more of the mass-production benefits that is core to all successful volume industries.

I have described how the Windcatcher system is scaling with number of turbines rather than increasing the size of the turbine. This allows for the support structures to be standardized and unlocks true economics of scale to the operations and maintenance of floating wind. Scaling by changing the number of identical turbines, with no influence on turbine design, blade lengths or even the supply chain also means the components of the system itself can be standardized, bringing added benefit to the project economics.

The Windcatcher system uses many small, low-complexity turbines. The number of turbines in each system means that we have a naturally high redundancy in a harsh operation environment.

Moreover, standardizing turbines and other power system components across projects means that operators can have unprecedented confidence in the availability of spares and even replacement units.

A low complexity design approach also lowers the entry barrier to floating wind for supply chain companies currently not present in that market space. It also means that the turbines in the Windcatcher can be mass produced in any relevant market region by a number of suppliers.

Bringing scale and standardization together is key to our vision of unleashing the power of offshore wind.

WCS insights November 2023

The current approach to floating wind has been to transition an idea that works well for both fixed installations, and float it. Maximizing the energy yield per turbine has been essential to reducing the cost for bottom-fixed wind installations, but an aerodynamic approach is not delivering the cost saving results for floating wind where the support structures cannot keep up with the turbine arms-race.

Floating wind - This is how we scale for the energy transition

Ole Heggheim, CEO, Wind Catching Systems

Floating wind has a big part to play in the global energy transition, but will the land-based approach to scaling deliver the impact and cost reductions needed? There is a limit to the practical potential of onshore wind and solar installations. Most of the available wind resource offshore is found in areas where the water depths are too great for bottom-fixed installations. So, affordable, and scalable floating wind has to play a part in achieving the global energy transition.

The floating wind industry is in rough waters. The industry has been trying to take land-based wind generation business models and hope that they will happily float on the sea.

Supply chain issues plague the offshore wind industry in general, and floating wind projects around the world are hitting the breaks. There is no clear path to profitability. Hopes that costs would inevitably decline – following the solar path – have been dashed by supply chain constraints and inflation pressures. Flagship projects on both sides of the Atlantic are being put on hold.

The current approach to floating wind has been to transition an idea that works very well for both onshore and bottom-fixed installations, and float it.

The scaling method envisaged for floating wind originates in the aerodynamic approach that has proved so successful for land-based and bottom-fixed installations: Maximizing the energy yield per turbine has been essential to halving the cost for bottom-fixed wind installations over the last decade. An aerodynamic approach is not going to deliver the cost saving results for floating wind where the support structures cannot keep up with the turbine arms-race. Luckily, floating wind can be scaled with the number of standard turbines, avoiding the major challenges the industry faces as we push the limits of individual turbine capacity.

At Wind Catching Systems we come at the challenge of scaling from a hydrodynamic perspective: Maximizing the energy yield per floater is going to deliver the cost reductions needed for floating installations. In order to achieve this, you need to be able to scale up the units without breaking new technology barriers with each step. The answer to both challenges is a multi-rotor approach.

Our power capacity is scaled by changing the number of identical turbines, with no influence on turbine design, blade lengths or even the supply chain. This is opposed to single-rotor turbines, which meet significant new technology and logistical barriers with each increase in generator size, blade lengths and more. For onshore and bottom-fixed projects support structures are more easily adaptable to new models. For floating wind the systems for installation and maintenance are constantly running catch-up, and can never standardize to the degree where we get real cost reductions for the industry.

The Windcatcher technology is highly adaptable for project size and conditions. Operations and maintenance systems are based on the same core components and support structures across the model range. Irrespective of the size of the unit, mechanical and electrical components remain the same. This also means project developers can have strong confidence in supply chain and component availability.

Our mission at Wind Catching Systems is to establish floating wind as a sustainable and competitive energy source to support the global energy transition. To achieve this goal floating wind must scale up the energy yield per unit without sacrificing the ability to efficiently install and maintain the units.

In a hydrodynamic world the floater is the unit – and a multi-rotor approach is the way to deliver its potential.

WCS insights November 2023

Floating wind is hanging by a thread.

The cost and associated months of downtime from a tow to shore operation for major repairs hurts the economics of floating wind projects. Overcoming this challenge is key to making floating offshore wind a success.

Floating wind operations and maintenance – this is how we do it!

Ole Heggheim, CEO, Wind Catching Systems

Floating wind is hanging by a thread.

The cost and associated months of downtime from a tow to shore operation for major repairs hurts the economics of floating wind projects. The renewables growth required by governments scrambling to meet decarbonization targets is held back by high costs and operational models that assume that conventional onshore wind turbines can easily be operated maintained on a floating structure. Overcoming this challenge is key to making floating offshore wind a success.

Wind Catching Systems is a Norwegian business with a wholly different and efficient approach to installation, operations and maintenance of floating offshore wind. Our mission is to establish floating offshore wind as a sustainable and competitive energy source by offering the most efficient technology in the market.

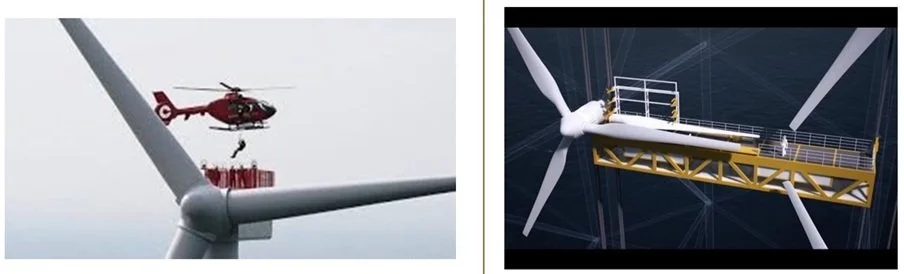

Our multi-rotor technology allows for each turbine to be small and light enough to be handled without the use of major cranes or specialized vessels. Moreover, with a multi-rotor set up, the failure of one turbine only represents a small fraction of the total system’s production. The result is higher uptime for the floating wind farm.

We are commercializing a disruptive elevator-based turbine installation and handling system. Instead of an expensive vessel towing a floating unit back to a port where it can be repaired, we reduce costs and increase renewable power generation by doing onboard repair and replacement. Thus, we can use a standard service vessel to access our floating units.

Without being dependent on large, specialized vessels and external support structures for our operations and maintenance, the Windcatcher will substantially lower the operations cost for floating offshore wind.

Floating wind is still in its infancy. New solutions and technology will have to be adapted if floating wind is to be able to affordably support the renewable energy transition. At Wind Catching Systems our ambition is to make affordable and reliable power from floating offshore wind a reality.

WCS Insights November 2023

Wind Catching technical development update

Wind Catching Systems has contracted Axess Group to design and develop the equipment handling system that is the key to WCS’ patented and disruptive operations and maintenance philosophy for floating wind.

Elevator-based operations in floating wind – we’re making it possible

Wind Catching Systems technical department

Wind Catching Systems (WCS) has contracted Axess Group (Axess) to design and develop the equipment handling system that is the key to WCS’ patented and disruptive operations and maintenance philosophy for floating wind.

Axess is a global services and solutions provider for the offshore energy industries. Through this contract WCS gets a reliable supplier with a solid track record from the energy and offshore business. Axess has its head office in Norway and over 20 offices throughout the main offshore energy markets around the world.

Axess brings hands-on experience from several existing floating offshore wind projects, including a cable pull-in system for the landmark Hywind Tampen project. Axess strongly believe in the need to rethink floating turbine operations and are excited to see that WCS are doing just this. Furthermore, Axess recognize that the material handling and O&M solution is key for the success of the overall technology, and WCS believe that the combination of experience, a broad service portfolio and product development expertise makes them a unique fit as a supplier to this system.

Having a successful track record of developing complex material handling systems for a wide range of applications, such as autonomous traverse cranes, flare tip replacement systems, manrider winches and more, Axess is able to apply this understanding to the technology development and design process.

Finally, Axess’ experience with managing regulatory compliance through both the design and operational lifetime of material handling systems will ensure that the system complies to all relevant regulatory requirements.